Информационный центр

Революция в дизайне рукояток: новые рычажные решения

В современном мире дизайн играет ключевую роль в улучшении функциональности и эстетики продуктов. Одной из областей, где инновации приносят значительные benefits, является дизайн рукояток. Рычажные решения, в частности, представляют собой революционный подход, который трансформирует то, как мы взаимодействуем с оборудованием, инструментами и повседневными объектами. Эта статья исследует новые тенденции в дизайне рукояток, фокусируясь на рычажных механизмах, их преимуществах, применениях и будущих направлениях. Мы углубимся в исторический контекст, современные технологии и практические примеры, чтобы предоставить comprehensive overview этой exciting темы.

Исторический контекст и эволюция дизайна рукояток

Дизайн рукояток имеет долгую историю, восходящую к древним временам, когда первые инструменты и оружие оснащались простыми деревянными или каменными ручками для улучшения контроля и уменьшения усилия. В средние века, с развитием металлургии, рукоятки стали более sophisticated, incorporating кованое железо и later сталь для increased durability. Industrial Revolution marked significant shift, as mass production introduced standardized handles for machinery, emphasizing functionality over form. Однако, often эти designs были громоздкими и неэргономичными, leading to user fatigue and accidents.

В 20-м веке, с advent of human factors engineering, дизайн рукояток начал evolve towards ergonomics. Исследования показали, что well-designed handles could reduce musculoskeletal disorders and improve productivity. Например, в automotive industry, рулевые колеса и рычаги переключения передач были redesigned to fit natural hand positions. Similarly, в промышленных settings, рукоятки для станков и инструментов стали lighter and more comfortable, using materials like plastics and composites. Despite these advancements, many handles still relied on traditional lever-based mechanisms, which were effective but limited in versatility.

Современная era, starting from the late 20th century, brought digitalization and advanced materials, enabling a revolution in handle design. Computer-aided design (CAD) and finite element analysis (FEA) allowed for precise modeling of stress points and user interaction. New materials, such as carbon fiber, thermoplastic elastomers, and smart polymers, offered enhanced strength, weight reduction, and adaptive properties. Additionally, the integration of electronics into handles, like sensors for feedback or control, opened up new possibilities. Рычажные решения, in particular, have benefited from these innovations, evolving from simple mechanical levers to complex, multifunctional systems that enhance user experience across various domains.

Что такое рычажные решения в дизайне рукояток?

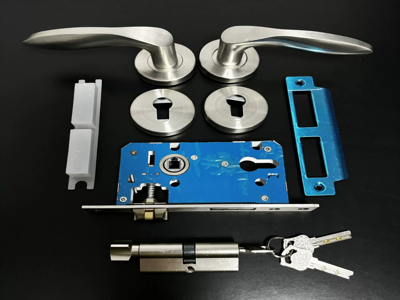

Рычажные решения refer to handle designs that incorporate lever mechanisms to amplify force, improve control, or enable precise movements. Essentially, a lever is a simple machine consisting of a rigid bar that pivots on a fulcrum, allowing small inputs to produce large outputs. In the context of handles, this can mean designs where the handle itself acts as a lever or is integrated with lever systems to enhance functionality. For example, a door handle might use a lever action to easily open a heavy door, or a tool handle might have a lever-based grip that reduces the effort needed for tasks like cutting or lifting.

Key characteristics of lever-based handle solutions include mechanical advantage, which allows users to apply less force for the same effect; ergonomic shaping, which ensures comfort and reduces strain; and versatility, as levers can be designed for various applications, from industrial machinery to consumer products. Modern lever solutions often incorporate additional features such as adjustable angles, locking mechanisms, or electronic integration for smart control. This makes them highly adaptable to different user needs and environments.

The evolution of lever solutions has been driven by advancements in materials science and engineering. Traditional levers were made from metals like steel or aluminum, but today, composites and polymers offer lighter weight and corrosion resistance. Furthermore, computational tools enable the optimization of lever geometry for maximum efficiency and safety. For instance, in automotive design, gear shift levers are now often designed with ergonomic contours and lightweight materials to provide a smooth, intuitive driving experience. Similarly, in medical devices, lever-based handles allow for precise control in surgeries or diagnostics, reducing practitioner fatigue and improving outcomes.

Преимущества новых рычажных решений

Новые рычажные решения offer numerous advantages over traditional handle designs. Firstly, они significantly improve ergonomics. By leveraging mechanical principles, these handles reduce the physical effort required from users, which is particularly important in repetitive tasks or high-stress environments. For example, in manufacturing, a lever-based handle on a tool can decrease operator fatigue by up to 30%, leading to higher productivity and fewer injuries. Studies have shown that ergonomic handles can reduce the incidence of conditions like carpal tunnel syndrome and tendinitis, which are common in industries involving manual labor.

Secondly, these solutions enhance safety. Lever mechanisms can include features such as fail-safes, locking systems, or overload protection, preventing accidents caused by slippage or misuse. In automotive applications, brake levers and steering handles are designed with safety in mind, ensuring reliable performance under various conditions. Additionally, the use of high-strength materials means that lever handles are more durable and less prone to failure, reducing maintenance costs and downtime.

Thirdly, new lever solutions contribute to efficiency and precision. In precision instruments, such as microscopes or surgical tools, lever-based handles allow for fine adjustments with minimal effort, improving accuracy and user control. In consumer products, like kitchen appliances or power tools, levers can simplify operations, making them more accessible to a wider audience. For instance, a lever on a coffee machine might enable easy brewing with consistent results, enhancing the overall user experience.

Moreover, these designs are often more aesthetically pleasing and customizable. With advanced manufacturing techniques like 3D printing, handles can be tailored to specific user preferences or brand identities. This not only improves functionality but also adds value through design, which is increasingly important in competitive markets. Environmental benefits also arise, as lightweight materials and efficient designs can reduce energy consumption and waste over the product lifecycle.

Ключевые тенденции в дизайне рукояток

Современные тенденции в дизайне рукояток heavily influenced by technology and user-centric approaches. One major trend is the integration of smart features. Handles are now being equipped with sensors, IoT connectivity, and haptic feedback, allowing for interactive experiences. For example, a lever handle on industrial equipment might monitor usage patterns and send alerts for maintenance, or a smart door handle could unlock via biometric recognition. This trend is driven by the broader adoption of Industry 4.0 and smart home technologies, where handles become part of connected ecosystems.

Another trend is the emphasis on sustainability. Designers are increasingly using recycled materials, biodegradable polymers, and eco-friendly production methods to create handles with a lower environmental impact. Lever solutions, due to their efficiency, can contribute to energy savings by reducing the force needed in operations, thus aligning with green initiatives. Additionally, modular designs that allow for easy repair or replacement of parts extend product lifespans and reduce waste.

Personalization is also gaining traction. With advances in additive manufacturing, handles can be custom-made to fit individual hand sizes or preferences, improving comfort and usability. This is particularly relevant in medical and assistive devices, where a one-size-fits-all approach is often inadequate. Lever mechanisms can be adjusted in terms of length, angle, or resistance, providing a tailored experience that enhances user satisfaction.

Furthermore, there is a growing focus on minimalist and intuitive design. Modern lever handles often feature clean lines, hidden mechanisms, and seamless integration with products, reflecting a trend towards simplicity and functionality. This not only improves aesthetics but also reduces cognitive load for users, making products easier to operate. For instance, in automotive interiors, lever handles for seats or controls are designed to be intuitive and unobtrusive, contributing to a smoother driving experience.

Применения в различных отраслях

Рычажные решения find applications across a wide range of industries, each benefiting from their unique advantages. In the automotive sector, lever handles are ubiquitous in gear shifts, parking brakes, and seat adjustments. New designs focus on lightweight materials like magnesium alloys or composites to reduce vehicle weight and improve fuel efficiency. Electronic shift levers, for example, use sensors and actuators to provide smooth, precise control, enhancing driver comfort and safety. Additionally, steering wheel handles with integrated levers for multimedia control are becoming common, offering convenience without distraction.

In industrial and manufacturing settings, lever-based handles are critical for tools and machinery. Power tools such as drills and saws often feature ergonomic lever grips that reduce vibration and fatigue, allowing operators to work longer with less strain. Heavy machinery, like cranes or excavators, uses lever handles for precise control of movements, improving accuracy and reducing the risk of accidents. The adoption of hydraulic or pneumatic levers in these applications provides powerful force amplification, making tasks that would otherwise be impossible manageable.

The medical field greatly benefits from lever solutions in devices ranging from surgical instruments to patient care equipment. For instance, adjustable hospital bed handles use levers to allow easy positioning for patients and caregivers, promoting comfort and safety. Surgical tools with lever mechanisms enable surgeons to perform delicate procedures with enhanced precision, reducing operative time and improving outcomes. Moreover, assistive devices like walking aids or wheelchair handles incorporate levers for better stability and ease of use, empowering individuals with disabilities.

Consumer products also see widespread use of lever handles. In home appliances, such as refrigerators or ovens, lever handles provide easy access and a modern look. Kitchen tools like can openers or peelers use lever actions to simplify tasks, making cooking more enjoyable. Even in sports equipment, such as bicycles or gym machines, lever handles offer adjustable resistance and control, enhancing performance and safety. The versatility of lever solutions ensures their relevance in virtually any domain where human interaction with objects is involved.

Материалы и технологии, используемые в новых решениях

The advancement of lever-based handle designs is closely tied to innovations in materials and technologies. Traditional materials like steel and aluminum are still used for their strength and durability, but they are often supplemented or replaced by newer options. Composite materials, such as carbon fiber reinforced polymers, offer high strength-to-weight ratios, making them ideal for applications where weight reduction is critical, like in aerospace or automotive industries. These materials can be molded into complex shapes, allowing for ergonomic designs that fit naturally in the hand.

Thermoplastic elastomers (TPEs) and other polymers are popular for their flexibility, comfort, and resistance to chemicals and wear. They are often used in grips and covers for handles, providing a non-slip surface that enhances safety. Additionally, smart materials like shape memory alloys or polymers can be incorporated into lever mechanisms to create adaptive handles that change properties in response to temperature or stress, offering dynamic functionality.

From a technological standpoint, computer-aided design (CAD) and simulation tools have revolutionized handle development. Engineers can model lever systems virtually, testing for stress, fatigue, and user interaction before physical prototypes are made. This reduces development time and costs while ensuring optimal performance. Additive manufacturing, or 3D printing, allows for rapid prototyping and customization, enabling the creation of handles with intricate internal structures that would be impossible with traditional methods.

Electronics integration is another key technology. Sensors embedded in handles can monitor usage, provide feedback, or enable control functions. For example, a lever handle with force sensors can adjust resistance based on user input, or with IoT connectivity, it can communicate with other devices for automated processes. Haptic technology can simulate tactile feedback, making digital interfaces more intuitive. These technologies are pushing the boundaries of what lever handles can do, transforming them from passive components into active, intelligent systems.

Влияние на пользовательский опыт

Новые рычажные решения have a profound impact on user experience (UX) by making interactions more intuitive, comfortable, and efficient. In product design, UX is paramount, and handles are often the primary point of contact between the user and the product. A well-designed lever handle can significantly enhance satisfaction by reducing physical strain and cognitive effort. For instance, in consumer electronics, a lever-based button on a device might require less pressure to activate, preventing finger fatigue during extended use.

Ergonomics play a central role in this. Lever handles designed with human factors in mind ensure that forces are applied optimally, minimizing the risk of injury and maximizing comfort. This is especially important in professional settings, where users may interact with handles for hours on end. Positive UX leads to increased productivity, as users can focus on their tasks rather than struggling with uncomfortable or inefficient tools.

Safety and reliability also contribute to UX. Users feel more confident when handles are sturdy and predictable, which is achieved through robust lever mechanisms and quality materials. In high-stakes environments like healthcare or construction, this confidence can directly impact outcomes. Moreover, aesthetic considerations—such as sleek, modern designs—can evoke positive emotions and brand loyalty, further enhancing the overall experience.

Looking forward, as handles become smarter, UX will continue to evolve. Interactive features like touch-sensitive levers or voice control integration could make products even more user-friendly. The goal is to create seamless, effortless interactions that feel natural and empowering, ultimately driving adoption and satisfaction across various applications.

Будущие направления и инновации

Будущее дизайна рукояток with lever solutions is bright, with several exciting directions on the horizon. One area of innovation is the further integration of artificial intelligence (AI) and machine learning. AI could analyze user behavior to optimize handle designs in real-time, adapting to individual preferences or changing conditions. For example, a smart lever handle might adjust its resistance based on the user's grip strength or fatigue level, providing a personalized experience that improves over time.

Another direction is the development of bio-inspired designs. By studying natural systems, such as the leverage mechanisms in animal limbs or plant structures, engineers can create handles that are more efficient and sustainable. Biomimicry could lead to handles that self-heal, change shape, or harvest energy from the environment, reducing the need for external power sources.

Advances in nanotechnology may enable handles with superhydrophobic or antimicrobial surfaces, enhancing hygiene and durability. In medical or food processing applications, this could prevent contamination and improve safety. Additionally, the use of virtual reality (VR) and augmented reality (AR) in the design process could allow for more immersive testing and customization, ensuring that handles meet user needs before they are even manufactured.

Sustainability will remain a key focus, with research into circular economy principles. Handles designed for disassembly and recycling, or made from upcycled materials, will become more common. Lever solutions that reduce energy consumption, such as those in regenerative braking systems, will contribute to broader environmental goals. Ultimately, the future of lever handle design lies in creating solutions that are not only functional and beautiful but also responsible and adaptive to the evolving needs of society.

Заключение

Революция в дизайне рукояток, driven by новые рычажные решения, represents a significant leap forward in how we interact with the world around us. From improving ergonomics and safety to enabling smart, connected experiences, these innovations are transforming industries and enhancing user lives. As materials, technologies, and design philosophies continue to evolve, the potential for further advancements is limitless. By embracing these changes, designers and engineers can create handles that are not only tools but also partners in efficiency and comfort. The future holds exciting possibilities, and it is clear that lever-based solutions will remain at the forefront of this dynamic field.